Table of Contents

AAC blocks and concrete blocks are two popular building materials used in the construction industry. Both of these materials have their own unique features and benefits that make them suitable for different types of construction projects. In this article, we will explore the differences between AAC blocks and concrete blocks.

Understanding AAC Blocks

Autoclaved Aerated Concrete, or AAC, represents a revolutionary building material. These lightweight, high-strength blocks are crafted from a blend of cement, lime, fly ash, and water. The mixture undergoes a meticulous curing process in an autoclave, a high-pressure chamber utilizing steam. This process induces a chemical reaction, causing the blocks to expand and become porous. The outcome is a lightweight, highly insulating material with low density.

AAC blocks come in various sizes, from small bricks to large panels, and find application in construction for load-bearing walls, floors, and roofs. Their exceptional resistance to fire, moisture, and pests makes them particularly suitable for areas with challenging environmental conditions.

What are Concrete Blocks?

Concrete blocks, also known as cinder blocks, emerge from a mix of cement, sand, and gravel. This mixture is poured into molds and cured, resulting in dense and heavy blocks. Concrete blocks are commonly used for constructing load-bearing walls, retaining walls, and foundations.

These blocks offer versatility in terms of sizes and shapes, allowing customization to meet specific construction requirements. While concrete blocks exhibit high durability and resilience to extreme weather conditions, they are prone to cracking and moisture damage, potentially reducing their lifespan.

Differences between AAC Blocks and Concrete Blocks:

1. Weight Distinction:

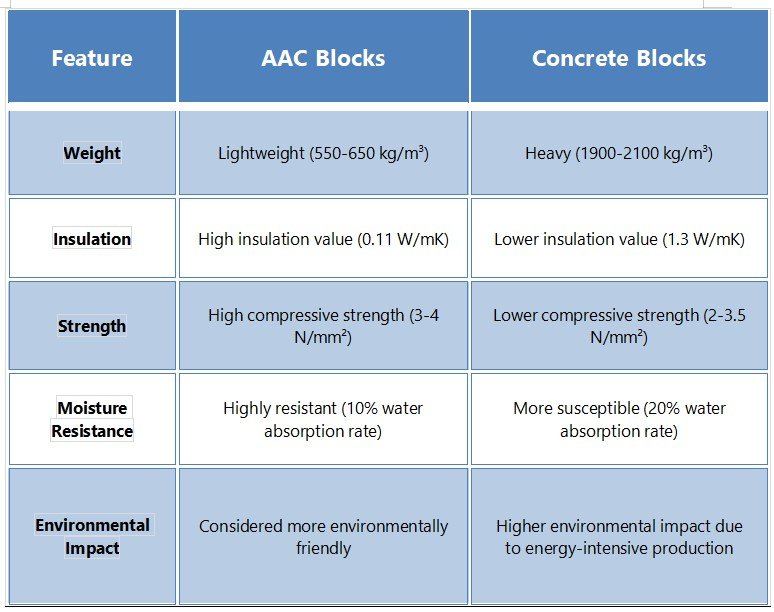

AAC blocks distinguish themselves by their lightweight nature, boasting a density of approximately 550 to 650 kg/m³. This characteristic facilitates easy handling and transportation while minimizing the load on the building’s foundation. In contrast, concrete blocks are significantly heavier, with a density ranging from 1900 to 2100 kg/m³.

2. Insulation Attributes:

The insulation properties of AAC blocks outshine concrete blocks. AAC blocks exhibit high insulation value, featuring a thermal conductivity of about 0.11 W/mK. This translates to superior temperature regulation, keeping buildings cool in summer and warm in winter. Conversely, concrete blocks display a lower insulation value, with a thermal conductivity of around 1.3 W/mK, potentially leading to higher energy bills for heating and cooling.

3. Strength Dynamics:

AAC blocks boast high durability and compressive strength, ranging from 3 to 4 N/mm², making them ideal for load-bearing walls and structures. On the other hand, concrete blocks present a lower compressive strength, ranging from 2 to 3.5 N/mm². However, they excel in resistance to impact and can withstand heavy loads.

4. Moisture Resistance:

AAC blocks showcase exceptional moisture resistance, with a low water absorption rate of around 10%. This feature makes them suitable for use in areas with high humidity and moisture levels. Conversely, concrete blocks exhibit a higher water absorption rate of about 20%, rendering them more susceptible to moisture damage and diminishing their lifespan.

5. Environmental Footprint:

AAC blocks emerge as the environmentally friendlier option when compared to concrete blocks. Their composition, involving natural materials like cement, lime, and fly ash, is both readily available and recyclable. In contrast, concrete blocks rely on a mixture of cement, sand, and gravel, demanding significant energy for production and transportation.

Concluding Thoughts

While both AAC blocks and concrete blocks find widespread use in construction, their distinctive properties and applications set them apart. AAC blocks, with their lightweight nature, superior insulation, and durability, prove ideal for load-bearing walls, floors, and roofs, demonstrating high resistance to fire, moisture, and pests. On the flip side, concrete blocks, though dense and heavy, lag behind in insulation properties. However, their durability and impact resistance make them a robust choice.

When builders and contractors face the choice between AAC blocks and concrete blocks, factors such as load-bearing capacity, insulation, moisture resistance, and environmental impact must be considered. Despite the higher initial cost of AAC blocks, their advantages in weight, insulation, and environmental impact can result in long-term cost savings and enhanced building performance.

If you want to know more about concrete block making machine, click here.

In conclusion, AAC blocks and concrete blocks, each with unique features and benefits, demand a thoughtful consideration of their differences. By discerning these disparities, builders and contractors can make informed decisions tailored to the specific requirements and desired outcomes of their construction projects.