Table of Contents

Introduction on Brick Selection:

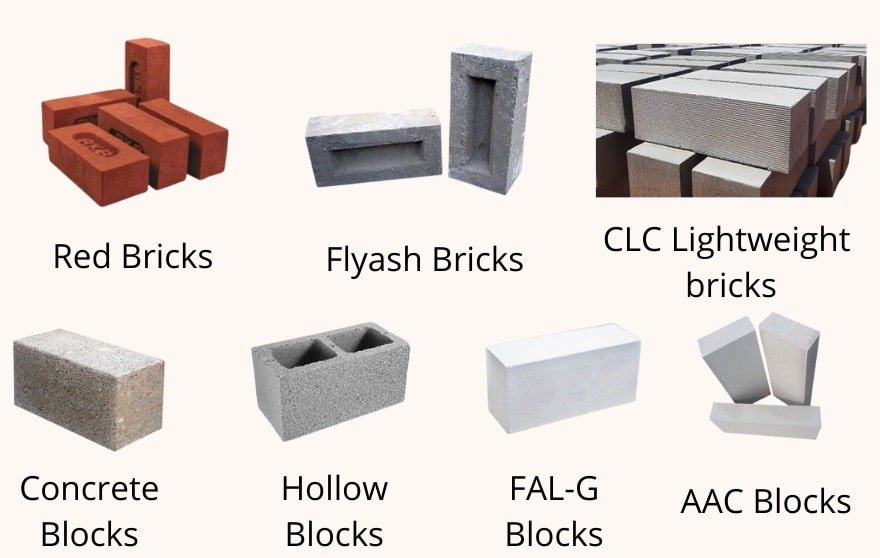

The use of bricks as a primary construction material has a rich history dating back to ancient times. In today’s construction landscape, an array of bricks and blocks are available, brick selection among them needs guidance with each offering distinct properties, advantages, and disadvantages. This guide aims to provide an in-depth overview of seven prominent types of bricks and blocks in the Indian construction industry.

1. Clay Brick:

Clay bricks, also known as burnt red bricks, have been a staple in construction for centuries. Crafted by molding wet clay, followed by drying and firing in kilns, these bricks are graded based on quality and strength.

| Properties | Advantages | Disadvantages |

|---|---|---|

| Average Strength: 30-35 kg/cm² | Wide Availability | Erosion of Topsoil |

| Water Absorption: 20-25% | Reliable Construction History | Air Pollution from Burning |

| Density: 1600-1700 kgs/cu.m | Versatility in Aesthetic and Functional Use | Uneven Shape and Finish |

| Thermal Resistance: Low | Long History of Reliable Use | Labor-Intensive Production |

| Sound Insulation: Low | Versatility for Aesthetic and Functional Purposes | Relatively High On-Site Waste |

2. Fly Ash Bricks:

Fly ash bricks, made from a blend of Fly ash, Stone Dust or Sand, Cement, and water, are renowned for their eco-friendly nature and precise manufacturing process.

| Properties | Advantages | Disadvantages |

|---|---|---|

| Average Strength: 50-75 kg/cm² | Uniform Shape and Size | Smaller Size, More Joints in Wall Construction |

| Water Absorption: 6-12% | Environmental Friendliness | Smooth Finish, Reduced Bonding with Concrete |

| Density: 1500-1600 kgs/cu.m | Large-Scale Production with Automatic Machines | – |

| Thermal Resistance: Moderate | Cost-Effective (Fly ash Availability) | – |

| Sound Insulation: Moderate | Utilization of Inexpensive Fly Ash | – |

3. CLC Lightweight Bricks:

Cellular Lightweight Concrete (CLC) Bricks, also known as Foam Concrete, are created by infusing a mixture of cement, fly ash, and water with protein-based foam.

| Properties | Advantages | Disadvantages |

|---|---|---|

| Average Strength: 35-50 kg/cm² | Lightweight, Reducing Structural Load | Limitations in Large-Scale Production |

| Water Absorption: 6-12% | Requires Less Plastering, Increasing Carpet Area | Increased Weight with Improved Strength |

| Density: 850-1000 kgs/cu.m | Larger Size, Reducing Joint Costs | Rough Finish Produced by Wire Cutting |

| Thermal Resistance: High | Superior Qualities – Thermal Resistance, Sound Insulation | – |

| Sound Insulation: High | Faster Construction | – |

4. Concrete Blocks:

Solid Concrete Blocks, a versatile option, are manufactured by blending Cement, Sand, Stone Chips, and water, catering to various applications.

| Properties | Advantages | Disadvantages |

|---|---|---|

| Average Strength: 75-200 kg/cm² | Ideal for Load-Bearing Purposes | Low Thermal Resistance |

| Water Absorption: 6-10% | Accurate Dimensions and Sharp Edges | Heavy and Challenging to Handle |

| Density: 1800-2400 kgs/cu.m | High-Strength Production with Automatic Machines | Requires Precision in Handling |

| Thermal Resistance: Low | Versatility in Construction Projects | – |

| Sound Insulation: Low | – | – |

5. Hollow Blocks:

Hollow Blocks, akin to Solid Concrete Blocks in composition, introduce a hollow space inside through partitioned molds.

| Properties | Advantages | Disadvantages |

|---|---|---|

| Average Strength: 35-45 kg/cm² | Lightweight Nature, Reducing Structural Load | Reduced Load-Bearing Capacity |

| Water Absorption: 8-10% | Larger Size Blocks, Minimizing Joint Requirements | Risky for Hanging Heavy Objects |

| Density: 1100-1500 kgs/cu.m | Good Insulation Properties – Sound, Heat, and Dampness | Increased Mortar Requirements for Construction |

| Thermal Resistance: Moderate | – | – |

| Sound Insulation: Moderate | – | – |

6. FaL-G Bricks:

FaL-G blocks, a blend of Fly ash, Lime, Gypsum, water, and optional sand, emerge as an eco-friendly construction material.

| Properties | Advantages | Disadvantages |

|---|---|---|

| Average Strength: 50-100 kg/cm² | Eco-Friendly, Utilizing Fly Ash | Smooth Surface Hindering Plaster Bonding |

| Water Absorption: 8-12% | Larger Size Blocks, Reducing Joint Requirements | Requires Additional Surface Preparation for Plastering |

| Density: 1400-1600 kgs/cu.m | Reduced Joint Requirements | – |

| Thermal Resistance: Moderate | – | – |

| Sound Insulation: Moderate | – | – |

7. AAC Lightweight Bricks:

Autoclaved Aerated Concrete (AAC) bricks, a lightweight alternative, are crafted from fly ash, gypsum, lime, cement, water, and aluminum powder.

| Properties | Advantages | Disadvantages |

|---|---|---|

| Average Strength: 30-50 kg/cm² | Reduces Building Dead Load | Requires Special Jointing Paste, High Precautions |

| Water Absorption: 8-12% | Superior Heat, Sound, and Seismic Resistance | High Water Absorption Leading to Cracks |

| Density: 650-750 kgs/cu.m | Larger Size Blocks, Faster Masonry Work | Brittle Nature Requires Careful Handling |

| Thermal Resistance: High | Easy Handling Due to Lightweight | Not Suitable for Load-Bearing |

| Sound Insulation: High | – | Longer, Thinner Screws Required for Cabinets and Wall Hangings |

Conclusion:

In the complex landscape of construction materials, the significance of informed brick selection cannot be overstated. Each type of brick or block carries its unique attributes, offering a nuanced blend of strengths and limitations. The decision-making process must encompass various factors such as project requirements, environmental considerations, and the delicate balance between structural strength and operational efficiency.

Efficiency in brick selection is further heightened by the advent of advanced brick making machines. These machines play a pivotal role in modern construction, automating and streamlining the production process. Employing innovative technologies, brick-making machines ensure uniformity, precision, and increased output, contributing to both cost-effectiveness and sustainability. Integrating these machines into the decision-making process enhances the overall efficiency of brick selection, enabling construction professionals to meet diverse project demands with greater ease and speed.

As the construction industry continues to evolve, the importance of strategic brick selection becomes increasingly evident. By leveraging the diversity of available bricks and embracing cutting-edge technologies such as brick-making machines, builders and architects pave the way for structures that not only stand the test of time but also align with contemporary standards of efficiency and sustainability. In essence, the journey towards optimal brick selection is not just a choice; it is a commitment to shaping a future where construction meets the demands of both the present and the generations to come.