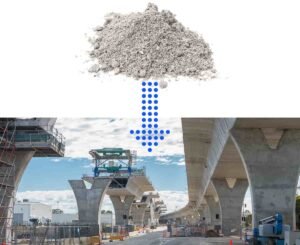

Fly ash bricks have become a popular alternative to traditional clay bricks due to their environmental benefits and cost-effectiveness. Fly ash, a waste product from coal-fired power plants, is used as a primary raw material in the production of these bricks. However, the manufacturing process for fly ash bricks is not without its challenges. Here are some common mistakes that manufacturers should avoid when producing fly ash bricks:

Not following the right mix ratio:

The right mix ratio is crucial to the quality of fly ash bricks. It is important to use the correct proportion of fly ash, cement, sand, and water to ensure that the bricks have the required strength and durability. A mix ratio that deviates from the recommended standard will result in poor quality bricks that will not meet industry standards. Manufacturers should ensure that they have the right equipment to measure and mix the materials in the correct proportion.

Not curing the bricks properly:

Proper curing is essential to the strength and durability of fly ash bricks. Curing involves the application of moisture and heat to the bricks to ensure that they reach their full strength potential. Failure to cure the bricks properly will result in weak and brittle bricks that are prone to cracking and breaking. Manufacturers should ensure that they have a proper curing process in place, which includes maintaining the correct temperature and humidity levels.

Ignoring quality control measures:

Quality control is critical in the manufacturing process of fly ash bricks. Manufacturers should have a quality control process in place to ensure that the bricks meet industry standards. This involves conducting regular tests to check the strength, durability, and uniformity of the bricks. Ignoring quality control measures can lead to poor quality bricks that will not meet industry standards, resulting in loss of reputation and business.

Using substandard raw materials:

Using substandard raw materials is a common mistake that manufacturers make. To ensure the quality of the bricks, it is essential to use high-quality raw materials. This includes using fly ash from reputable sources, high-quality cement, and sand. Using substandard raw materials will result in poor quality bricks that will not meet industry standards. Manufacturers should ensure that they source their raw materials from reputable suppliers who can provide quality assurance.

Not maintaining the production equipment:

Production equipment is critical to the manufacturing process of fly ash bricks. Failure to maintain the equipment can result in downtime and production delays, leading to loss of revenue. Manufacturers should ensure that they have a maintenance schedule in place for their equipment to avoid breakdowns and prolong the lifespan of the equipment.

Ignoring safety measures:

Safety is paramount in the manufacturing process of fly ash bricks. Manufacturers should ensure that they have safety measures in place to protect their workers and the environment. This includes using personal protective equipment, ensuring proper ventilation, and disposing of waste materials safely. Ignoring safety measures can lead to accidents, injuries, and environmental pollution, leading to legal and financial liabilities.

Conclusion:

Manufacturing fly ash bricks requires attention to detail and adherence to industry standards. Manufacturers should avoid common mistakes such as using substandard raw materials, ignoring quality control measures, and overloading the kiln. They should also ensure that they have a proper curing process in place, maintain their production equipment, and observe safety measures. By avoiding these mistakes, manufacturers can produce high-quality fly ash bricks that meet industry standards and contribute to a sustainable environment.