Introduction

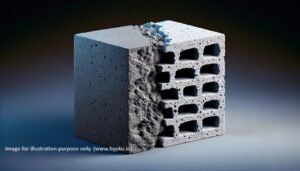

Compressed Stabilized Earth Blocks (CSEB) are a sustainable, eco-friendly building material made from a mix of soil, stabilizers, and water, compressed to form durable blocks. In a world where sustainability is becoming increasingly critical, CSEB blocks offer a compelling alternative to traditional building materials. They not only reduce the environmental impact but also provide numerous benefits that make them a preferred choice for modern construction.

Table of Contents

History of CSEB Blocks

Origin and Development

CSEB blocks have their roots in ancient construction techniques, where earth was used as a primary building material. The modern CSEB blocks, however, evolved in the mid-20th century, incorporating scientific advancements to enhance their strength and durability. The concept was developed as a response to the need for affordable, sustainable housing in developing countries.

Evolution Over Time

Initially, the blocks were manually compressed, but with technological advancements, automated machines were introduced, significantly improving production efficiency and block quality. Over time, the methods and materials have been refined, leading to the high-performance CSEB blocks we have today.

Composition of CSEB Blocks

Key Ingredients

CSEB blocks are primarily made from a mixture of soil, stabilizers (such as cement or lime), and water. The soil used must have a good proportion of clay and sand to ensure adequate binding and strength.

Role of Stabilizers

Stabilizers are crucial in enhancing the blocks’ strength and durability. Cement is commonly used, but alternatives like lime can also be effective, depending on the soil type and desired block properties.

Manufacturing Process

Steps in CSEB Block Production

Soil Selection: The first step is to choose suitable soil, which is then sieved to remove large particles.

Mixing: The soil is mixed with stabilizers and water to achieve the right consistency.

Compression: The mixture is poured into a mold and compressed using a manual or hydraulic press.

Curing: The blocks are then cured for several days to attain the necessary strength.

Equipment Used

The manufacturing process involves various equipment, including soil mixers, sieves, and compression machines. Automated presses are often used for large-scale production, ensuring uniformity and quality.

Benefits of CSEB Blocks

Environmental Advantages

CSEB blocks are highly sustainable as they use locally available materials, reducing transportation costs and emissions. They also have a lower carbon footprint compared to traditional bricks and concrete blocks.

Economic Benefits

These blocks are cost-effective due to the use of local materials and simpler manufacturing processes. They also provide energy savings as they offer excellent thermal insulation, reducing the need for heating and cooling.

Health and Comfort

CSEB blocks promote a healthier living environment as they are breathable, reducing humidity and mold growth. Their thermal properties also contribute to comfortable indoor temperatures.

Comparing CSEB Blocks with Other Materials

CSEB vs. Traditional Brick

CSEB blocks are more environmentally friendly and cost-effective than traditional bricks. They require less energy to produce and offer better insulation properties.

CSEB vs. Concrete Blocks

While concrete blocks are strong, they have a higher environmental impact due to the cement production process. CSEB blocks offer a more sustainable and affordable alternative with sufficient strength for most applications.

Applications of CSEB Blocks

Residential Buildings

CSEB blocks are widely used in residential construction, providing durable and aesthetically pleasing homes. Their natural appearance blends well with various architectural styles.

Commercial Structures

These blocks are also suitable for commercial buildings, offering the same benefits of durability, cost-effectiveness, and sustainability.

Community Projects

CSEB blocks are often used in community projects like schools and clinics, especially in developing regions where affordability and sustainability are crucial.

Construction Techniques with CSEB Blocks

Basic Building Methods

Building with CSEB blocks is similar to traditional bricklaying. Blocks are laid in a staggered pattern and bonded with mortar. Openings for doors and windows are easily accommodated.

Advanced Techniques

Advanced techniques include reinforced CSEB construction, where steel reinforcements are integrated for added strength, making it suitable for multi-story buildings.

Durability and Maintenance

Longevity of CSEB Structures

With proper construction and maintenance, CSEB buildings can last for decades. The blocks’ natural properties make them resistant to weathering and pests.

Maintenance Tips

Maintenance is relatively simple and involves periodic inspections to repair any cracks or damages. Applying protective coatings can also enhance durability.

Challenges in Using CSEB Blocks

Common Issues

Challenges include variability in soil quality, which can affect block strength, and the need for skilled labor to ensure proper construction techniques.

Overcoming Challenges

These challenges can be mitigated through thorough soil testing, training for builders, and adherence to quality standards during production and construction.

Sustainability Impact

Carbon Footprint Reduction

CSEB blocks significantly reduce carbon emissions compared to conventional building materials, contributing to global efforts to combat climate change.

Resource Efficiency

The use of locally sourced materials minimizes resource depletion and transportation emissions, enhancing the overall sustainability of construction projects.

Future of CSEB Blocks

Innovations and Trends

The future of CSEB blocks looks promising with ongoing innovations such as improved stabilizer formulas, automated production techniques, and integration with renewable energy sources.

Market Potential

As the demand for sustainable building materials grows, the market potential for CSEB blocks is expected to expand, offering new opportunities for businesses and builders.

How to Source CSEB Blocks

Finding Suppliers

CSEB blocks can be sourced from specialized manufacturers and suppliers. It’s essential to choose reputable suppliers who adhere to quality standards.

Quality Assurance

Ensure the blocks meet specific standards for strength and durability by requesting certifications and conducting independent tests if necessary.

Conclusion

CSEB blocks represent a sustainable, cost-effective, and versatile building material that holds immense potential for the future of construction. By leveraging local resources and adopting eco-friendly practices, CSEB blocks offer a pathway to more sustainable living and building.

Frequently Asked Questions (FAQs)

What are CSEB blocks made of?

CSEB blocks are made from a mixture of soil, stabilizers like cement or lime, and water, which is then compressed to form durable blocks.

How do CSEB blocks compare in cost to traditional bricks?

CSEB blocks are generally more cost-effective than traditional bricks due to lower material and production costs and their energy-saving properties.

Are CSEB blocks suitable for all climates?

Yes, CSEB blocks are versatile and can be used in various climates. They provide excellent thermal insulation, making them suitable for both hot and cold environments.

What is the lifespan of a building made with CSEB blocks?

With proper construction and maintenance, CSEB buildings can last for several decades, often comparable to buildings made with conventional materials.

Can I make CSEB blocks myself?

Yes, with the right equipment and materials, you can produce CSEB blocks. However, ensuring the correct soil mix and compression technique is crucial for quality and durability.