Introduction:

Fly ash is a byproduct of coal combustion that is being accumulated as waste material in large quantities near thermal power plants. The disposal of fly ash has become a major environmental concern due to its potential to contaminate soil and water resources. However, fly ash can also be used as a raw material for the manufacture of building materials such as bricks. Fly ash bricks are lightweight, durable, and have good thermal insulation properties. They are also cost-effective compared to traditional clay bricks.

In recent years, researchers have been exploring ways to enhance the strength and durability of fly ash bricks. One promising approach is to add industrial waste materials such as steel slag and tapioca powder to the mix. Steel slag is a byproduct of steel production that contains high levels of calcium, iron, and silicon. Tapioca powder is a starch extracted from cassava roots that has binding properties.

This article discusses a study conducted by V. Aravind et al., which investigated the use of steel slag and tapioca powder in the manufacture of fly ash bricks.

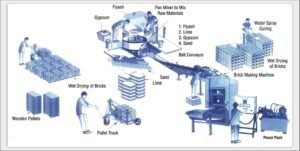

Methodology:

The study involved preparing four different mixes of fly ash brick samples: (1) control mix without any additives, (2) mix with 5% tapioca powder, (3) mix with 5% steel slag, and (4) mix with 2.5% tapioca powder + 2.5% steel slag. The samples were then tested for compressive strength, water absorption, and density.

Results:

The results showed that the addition of steel slag and tapioca powder improved the compressive strength and water absorption properties of fly ash bricks. The highest compressive strength was observed in sample 4 (with 2.5% tapioca powder + 2.5% steel slag), which had an average strength of 9.5 MPa. This was a significant improvement compared to the control mix, which had an average strength of 6.5 MPa.

The water absorption properties of the samples were also improved with the addition of steel slag and tapioca powder. The lowest water absorption was observed in sample 4, which had an absorption rate of 10.2%. This was a significant improvement compared to the control mix, which had an absorption rate of 16.8%.

Discussion:

The results of this study suggest that the addition of steel slag and tapioca powder can significantly improve the strength and durability properties of fly ash bricks. The improvement in compressive strength can be attributed to the high levels of calcium and iron in steel slag, which react with the fly ash to form a stronger bond. Tapioca powder, on the other hand, acts as a binding agent that helps to hold the particles together.

The improvement in water absorption properties can be attributed to the porous structure of fly ash bricks. The addition of steel slag and tapioca powder helps to fill in the pores and reduce the amount of water that can penetrate into the brick. This makes the bricks more resistant to moisture damage and improves their overall durability.

In addition to improving the strength and durability properties of fly ash bricks, the use of steel slag and tapioca powder also has environmental benefits. Steel slag is a waste material that is produced in large quantities by steel plants. By using it as a raw material for building materials, we can reduce its environmental impact and conserve natural resources. Tapioca powder is also a renewable resource that is biodegradable and non-toxic.

Conclusion:

The study conducted by V. Aravind et al. demonstrates that the addition of steel slag and tapioca powder can significantly improve the strength and durability properties of fly ash bricks. The use of these industrial waste materials not only enhances the performance of building materials but also has environmental benefits by reducing waste generation and conserving natural resources.Fly ash bricks are an excellent alternative to traditional clay bricks due to their lightweight, durability, thermal insulation properties, and cost-effectiveness. With further research into innovative manufacturing techniques such as using industrial waste materials like steel slag and tapioca powder, we can continue to improve their performance while reducing their environmental impact.In conclusion, this study provides valuable insights into how we can enhance building materials’ performance while promoting sustainable development practices. By adopting these innovative approaches, we can create a more sustainable future for ourselves and future generations.

This article provides valuable insights into the innovative use of fly ash, steel slag, and tapioca powder in brick manufacturing. It’s encouraging to see how industrial byproducts can be repurposed to enhance the strength and durability of building materials while also benefiting the environment. The findings on water absorption and compressive strength improvements are particularly impressive. For those interested in other sustainable building solutions, you may find this overview on Pre-Engineered Buildings insightful.