Disadvantages:

Concrete is a popular construction material that is often enhanced with fly ash to improve its performance. However, using fly ash in concrete has some noticeable drawbacks. Here are some disadvantages of using fly ash in concrete:

Slow Strength Gain: While concrete solidifies within hours of pouring, its curing process takes longer. Fly ash can increase the time concrete takes to reach its full strength, which can be problematic as slow strength gain directly affects the speed of construction.

Longer Setting Times: The addition of fly ash can increase the time concrete takes to settle, which can be inconvenient and delay construction. In such cases, other admixtures may be required to adjust the set time of the concrete, depending on the percentage of fly ash in the mixture and the outside temperature.

Poor Air Content Control: Air-entraining admixtures can create tiny air bubbles in concrete, which protect it from damage caused by freeze/thaw cycles. Fly ash reduces the amount of air entrainment, so concrete mixtures high in fly ash may require more air-entraining admixture.

Seasonal Restrictions: Concrete pouring is challenging during the winter season, and mixtures high in fly ash are even more susceptible to low temperatures. Low temperatures increase setting times and cause slow strength gain, even in concrete mixtures without fly ash. When fly ash is added, it can exacerbate these issues.

Color Inconsistency: Fly ash can cause visual inconsistencies on the finished surface of concrete, such as dark streaks resulting from carbon particles. This can make it more difficult to control the color of the concrete.

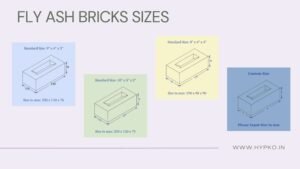

Size Limitations: Fly ash bricks have size limitations, and only modular size bricks can be produced. Larger bricks are more prone to breakage and cracking.

Restricted Suitability: Only fly ash produced in power plants is usually compatible with concrete, and other fly ash may require beneficiation. It is crucial to use only high-quality fly ash to avoid negative effects on the structure.

In addition to these disadvantages, poor quality fly ash bricks can negatively impact the structure of the concrete. If bricks are not prepared properly, they may have no strength and increase permeability, resulting in damage to the structure. The smooth surface of fly ash bricks also leads to lower bonding with the concrete. Finally, fly ash bricks are only suitable for subtropical areas or warm atmospheres, as they do not retain heat and are not effective in the winter season.

Advantages of Fly Ash Bricks:

Fly ash bricks offer a wide range of benefits compared to traditional clay bricks. Here are some of the advantages:

Attractive Appearance:

Fly ash bricks have a pleasing cement-like color, uniform size, and smooth finish, making them visually appealing. Due to their uniform size, less mortar is needed for walls and plastering, resulting in a 40-50% reduction in mortar consumption. The bricks are free from cracks, organic matter, wrap age, pebbles, and nodules of free lime, making them ideal for construction projects.

High Strength:

With a compressive strength of 9-10 N/mm2, fly ash bricks are significantly stronger than traditional clay bricks. This strength reduces breakages/wastages during transport and handling, and the lower thickness of joints and plaster reduces cracking in plaster. These bricks do not cause any additional load for the design of structures and provide better earthquake resistance. They improve strength over time and provide greater strength to the structure.

Thermal Properties:

Fly ash bricks have a thermal conductivity of 0.90 – 1.05 W/m2, which is lower than that of traditional clay bricks. They acquire less heat, and the pozzolanic reaction between fly ash and lime generates less heat. These properties keep buildings cooler in summer, making fly ash bricks ideal for use in hot climates.

Durability:

Fly ash bricks are extremely durable and less permeable. Their lower permeability efficiently decreases the effect of efflorescence on bricks, and they are less porous, absorb less water, and decrease dampness on the walls. They are highly resistant to attack by moderate acid, water, and sulfate, making them ideal for use in harsh environments.

Sound Insulation:

Construction with fly ash bricks provides decent sound insulation to the building.

Fire Resistance:

Fly ash bricks are highly fire-resistant, making them ideal for use in buildings that require high levels of fire safety.

Sustainability:

Fly ash bricks are eco-friendly, as they are made of waste materials that come from the combustion of coal in thermal power plants. This process generates no pollution or environmental damage and is considered a white class product.

Easy Workability:

Fly ash bricks have easy workability and absorb less water, reducing the need for soaking in water for 24 hours. Sprinkling water before use is adequate, and the construction method is the same as clay brick construction, requiring no additional training for the masons.

Availability:

Fly ash bricks are usually available close to thermal power plants, but dealers can also be found in all major cities and towns.

Cost-Effective:

The same number of fly ash bricks can cover more area compared to clay bricks, and consumption of mortar is also lower. They require less labor, and the cost of fly ash bricks is approximately 30% lower than that of clay bricks.

Applicability:

Fly ash bricks are lightweight, making them suitable for multi-story structures. Their low weight means less stress on the building, and they can be used in load-bearing external walls in low/mid structures, non-load bearing internal walls in low/mid structures, and non-load bearing internal or external walls in high-rise buildings.

Conclusion:

Fly ash is a byproduct of coal combustion in thermal power plants, and it is commonly used as an admixture in concrete to enhance its properties. However, using fly ash in concrete has some disadvantages, such as slow strength gain, longer setting times, poor air content control, seasonal restrictions, color inconsistency, size limitations, and restricted suitability. In addition, poor quality fly ash bricks can negatively impact the structure of the concrete.

On the other hand, fly ash bricks offer a wide range of advantages over traditional clay bricks. They have an attractive appearance, high strength, good thermal properties, durability, sound insulation, fire resistance, sustainability, easy workability, availability, cost-effectiveness, and applicability to different types of buildings.

Overall, fly ash bricks are a popular choice for builders looking for a durable, cost-effective, and sustainable building material, and their advantages outweigh the disadvantages of using fly ash in concrete.