Table of Contents

Fly ash, a byproduct of coal combustion, has long served as a supplementary cementitious material in concrete, imparting enhanced workability, durability, and strength. However, its initial low hydration poses a challenge to the compressive strength of fly ash bricks. This study delves into identifying the optimal mix percentage for fly ash bricks by incorporating lime, gypsum, and quarry dust to augment compressive strength.

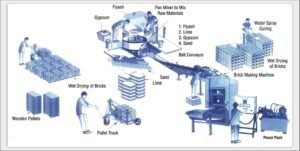

Experiment Setup and Mix Proportions for Improving Compressive Strength of Fly Ash Brick

Brick specimens, sized at 230mm x 110mm x 90mm, were cast for varying mix percentages of fly ash (15% to 50%), gypsum (2%), lime (5% to 30%), and quarry dust (45% to 55%). Compressive strength was assessed across different curing ages, revealing variations based on the mix proportions.

Results and Optimization

The study inferred that the peak compressive strength occurs at an optimized mix percentage of Flyash – 15%, Lime – 30%, Gypsum – 2%, and Quarry dust – 53%. Key study terms include Fly ash, Lime, Gypsum, Quarry dust, Compressive strength, and Water absorption.

Unveiling Solutions: Taguchi Method Application

The study addresses the challenge of low early-stage hydration in fly ash bricks through an innovative approach. Utilizing the Taguchi method, the mix proportions were experimentally explored, minimizing cement and fly ash quantities while controlling the water-binder ratio. The effects of water/binder ratio, fly ash, coarse sand, and stone dust on performance characteristics were scrutinized using signal-to-noise ratios and mean response data.

Optimal Mix Percentage Validation

The research demonstrates that optimizing the mix percentage of fly ash, lime, gypsum, and quarry dust significantly enhances the compressive strength of fly ash bricks. The pinnacle of compressive strength was achieved at Flyash – 15%, Lime – 30%, Gypsum – 2%, and Quarry dust – 53%. This finding underscores the efficacy of incorporating small amounts of additional materials to fortify fly ash bricks.

Positive Impacts of Additives: Lime, Gypsum, and Quarry Dust

The inclusion of lime and gypsum in fly ash bricks positively influences compressive strength. Lime improves workability and durability, while gypsum acts as a retarder, delaying the setting time. Quarry dust, a byproduct of stone crushing, also contributes positively to compressive strength, offering an alternative to sand in concrete or bricks.

Addressing Water Absorption Characteristics

Apart from bolstering compressive strength, this study examines the water absorption properties of fly ash bricks. Water absorption, crucial for durability and weathering resistance, displayed a decrease with higher fly ash content and prolonged curing time.

Comprehensive Insights and Sustainable Solutions

In summary, this research not only showcases the significance of optimizing mix proportions for fly ash bricks but also sheds light on improving performance characteristics without a substantial cost increase. The findings underscore the possibility of strengthening fly ash bricks without compromising other essential properties like water absorption.

Conclusion: Elevating Durability through Optimized Mix Proportions

In conclusion, the meticulous optimization of mix proportions for fly ash bricks, as revealed through this study, signifies a pivotal breakthrough in the construction industry. The identified optimal blend of Flyash – 15%, Lime – 30%, Gypsum – 2%, and Quarry dust – 53% not only maximizes compressive strength of fly ash brick but also offers a cost-effective strategy for fortifying these bricks. This achievement is not merely confined to a laboratory outcome; it resonates as a transformative solution that architects and builders can leverage to create resilient structures without compromising on sustainability.

Beyond the realm of compressive strength of fly ash brick, the positive influences of lime, gypsum, and quarry dust underscore a paradigm shift towards environmentally conscious construction practices. These additives not only enhance the material’s performance but also contribute to its longevity and resistance to weathering. As we navigate towards a future where construction is synonymous with sustainability, this research serves as a guiding light, emphasizing the importance of nuanced mix proportions in shaping structures that endure, both in strength and environmental responsibility.