When delving into the world of construction materials, it’s common to encounter various types of bricks, each with its unique properties, benefits, and applications. Among these, fly ash brick and Autoclaved Aerated Concrete (AAC) brick stand out for their eco-friendly credentials and performance. However, despite some similarities, these materials are not the same and cater to different requirements in the construction industry.

Contents

Understanding Fly Ash Brick

Composition and Manufacturing

Fly ash brick is made from fly ash, a byproduct of coal combustion in power plants, combined with water, sand, and lime. These ingredients are mixed together and then molded under high pressure. The bricks are then cured, either by air drying or through the use of steam. This process makes fly ash bricks strong, durable, and resistant to various environmental factors.

Key Features and Benefits

- Environmental Friendliness: Utilizes waste materials, reducing landfill space and lowering carbon emissions.

- Durability: High strength and uniform shape increase the longevity of constructions.

- Cost-Effective: Generally cheaper than traditional bricks due to the abundance of raw materials.

Exploring AAC Brick

Composition and Manufacturing

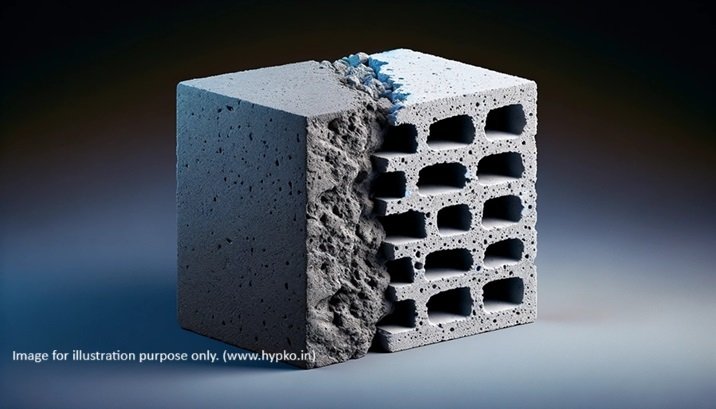

AAC brick, on the other hand, is a lightweight, precast foam concrete building material. It’s made from a mixture of sand, lime, cement, water, and a foaming agent. This mixture is then poured into molds and allowed to rise, similar to dough. Once it has set, the material is cut into blocks or panels and then autoclaved under high pressure and temperature. This process gives AAC its distinct porous structure and lightweight nature.

Key Features and Benefits

- Lightweight: AAC bricks are lighter than traditional bricks, reducing the dead load on structures.

- Thermal Insulation: Offers excellent thermal insulation, leading to energy savings in buildings.

- Fire Resistance: Provides superior fire resistance compared to many traditional building materials.

Fly Ash Brick vs. AAC Brick: A Comparison

While both materials are celebrated for their sustainability and performance, there are key differences:

- Manufacturing Process: Fly ash bricks are pressure cured, while AAC bricks undergo an autoclaving process.

- Weight: AAC bricks are significantly lighter, affecting the handling and transportation costs.

- Insulation Properties: AAC offers better thermal and sound insulation compared to fly ash bricks.

- Cost: The initial cost of AAC bricks can be higher, but this is often offset by the reduced structural and insulation costs.

Table of Differences: Fly Ash Brick vs. AAC Brick

To succinctly outline the distinctions between Fly Ash Brick and AAC Brick, the following table compares various aspects of these two popular construction materials:

| Feature | Fly Ash Brick | AAC Brick |

|---|---|---|

| Composition | Fly ash, water, lime, and sand. | Sand, lime, cement, water, and a foaming agent. |

| Manufacturing Process | Mixture is pressure-cured (air drying or steam). | Mixture is poured into molds, rises, cut into shapes, and autoclaved under high pressure and temperature. |

| Weight | Heavier compared to AAC. | Significantly lighter, reducing structural load. |

| Insulation Properties | Moderate thermal insulation. | Excellent thermal and sound insulation due to its porous structure. |

| Fire Resistance | Good fire resistance. | Superior fire resistance compared to fly ash brick. |

| Environmental Impact | Reduces landfill space by utilizing industrial waste. | Produces less CO2 during manufacturing; improves energy efficiency in buildings due to better insulation. |

| Cost | Generally lower due to the abundant availability of raw materials. | Initially higher, but can lead to savings in structural and insulation costs. |

| Application | Suitable for load-bearing and non-load-bearing structures, depending on the strength. | Preferred in projects prioritizing light weight, thermal insulation, and speedy construction. |

This table highlights the fundamental differences between Fly Ash Brick and AAC Brick, helping stakeholders in the construction industry make informed choices based on their project’s specific requirements.

FAQs

What is better for residential construction, fly ash or AAC brick?

The choice depends on specific project requirements. For projects prioritizing cost and durability, fly ash bricks may be preferred. For those emphasizing insulation, lightweight, and speed of construction, AAC bricks could be more suitable.

Can fly ash bricks be used in load-bearing structures?

Yes, fly ash bricks have high compressive strength and can be used in load-bearing structures, provided they meet the specific strength requirements of the construction.

Are AAC bricks environmentally friendly?

Yes, AAC bricks are considered environmentally friendly due to their production process, which uses fewer raw materials and emits less CO2 compared to traditional bricks. Additionally, their thermal insulation properties contribute to energy efficiency in buildings.

Conclusion

While fly ash brick and AAC brick share the common goal of providing sustainable building materials, they differ significantly in composition, manufacturing, and application. The choice between the two should be based on the specific needs of the construction project, including considerations of cost, structural requirements, and environmental impact. By understanding these differences, builders and architects can make informed decisions to meet their project’s goals efficiently and sustainably.

It’s really fantastic and useful informations.

I appreciate this document. Please send me more informations about the scientific processus of making fly ash,compressed stabilized earth blocks, mud blocks etc.

Make your document possible translation in french or english.

Thanks warmly for your support and cooperation.

Malick Thierno Sow Dakar Senegal

Thanks for the appreciation sir. We will surely try to do as suggested by you. We would come with posts on more clear information about CSEB and mud bricks.