Table of Contents

Introduction: AAC Blocks vs Fly Ash Bricks in Contemporary Architecture

When examining wall construction materials, two contenders emerge: AAC Blocks and Fly Ash Bricks. To make an informed decision between AAC Blocks vs Fly Ash Bricks, we delve into their distinct features, their preparation techniques, and their respective roles in modern construction.

Understanding Fly Ash Bricks

The Basics of Fly Ash Bricks in the AAC Blocks vs Fly Ash Bricks Debate

Fly ash bricks serve as indispensable masonry units in the construction realm. These bricks consist of fly ash, sand, cement, and gypsum. Sometimes, they also incorporate Ordinary Portland cement. By transforming fly ash, a byproduct from thermal plants, into these bricks, we can mitigate its potentially hazardous environmental impacts.

The Making of Fly Ash Bricks: A Critical Element in the AAC Blocks vs Fly Ash Bricks Discussion

The crafting of fly ash bricks entails mixing fly ash, sand, cement, and gypsum with water. The resulting semi-dry mixture undergoes compression in a mechanical press with a force reaching up to 28 MPa. These bricks, once formed, undergo a drying process, first in sunlight for a day or two, followed by air drying in the shade. The curing process, a vital stage, requires the bricks to undergo a steam bath at 66° C, lasting anywhere from 14 to 21 days.

Key Features of Fly Ash Bricks

- Environmental Benefit: Converts potentially harmful fly ash into eco-friendly bricks.

- Resistance: Offers strong protection against acid and sulfate attacks.

- Fire Resistant: Primarily ash-made, these bricks provide solid fire resistance.

- Low Water Absorption: Only about 15 percent, proving advantageous in certain settings.

- Lightweight: Facilitates easier handling during construction.

However, their limitation lies in thermal conductivity, making them unsuitable for colder regions and areas far from thermal plants due to economic constraints.

Diving into Autoclaved Aerated Concrete Blocks (AAC Blocks)

AAC Blocks: A Strong Contender in AAC Blocks vs Fly Ash Bricks

AAC blocks, another revolution in the masonry realm, are composed of lime, sand (often inclusive of fly ash), cement, and an admixture like aluminum paste. These blocks stand out due to their micro air-entrained characteristic, rendering them impressively lightweight. The chemical reactions between components not only provide structural strength but also contribute to the block’s unique cellular structure.

Crafting Process of AAC Blocks

The making of AAC blocks begins by mixing lime, sand, cement, and admixtures with water. The resultant mix is dosed out and shaped before undergoing autoclaving – a heat and steam pressure treatment. This crucial step also serves as a curing process. Freshly autoclaved blocks, known as green cakes, undergo demolding and cutting processes to fit varied construction requirements.

Salient Features of AAC Blocks

- Micro Pore Presence: These micropores range from 1mm-5mm, contributing to the block’s unique structure.

- Lightweight & Insulating: They offer excellent thermal and sound insulation, making them perfect for specialized constructions like auditoriums.

- Moisture Resistance: Despite the pores, these blocks resist moisture efficiently.

- Eco-friendly: Utilizes naturally available materials and produces no harmful byproducts.

But, it’s worth noting that while these blocks showcase high compressive strength, they’re not recommended for structural construction without supplementary support.

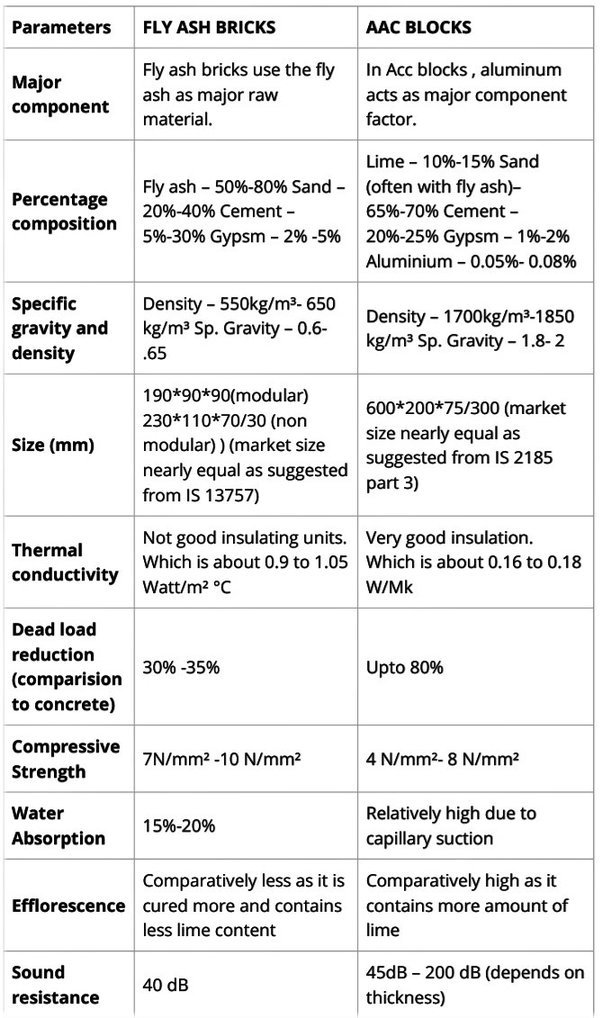

AAC blocks vs Fly ash bricks: Head-to-Head

AAC Blocks vs Fly Ash Bricks: The Final Verdict

Both AAC blocks and fly ash bricks are invaluable in wall construction. The former, crafted from waste byproducts, stands resilient against potential threats like acid and sulfate. However, they might not be the optimal choice for colder regions. Conversely, AAC blocks, with their lightweight and insulative properties, serve varied purposes in construction but might require additional support for structural applications.

Both have carved a niche for themselves in the construction domain, and their choice primarily depends on the specific requirements and environmental considerations of a project.

For a deeper dive into various brick types and their properties, one can refer to “A Guide to Choosing the Right Bricks and Blocks for Construction in India”. This comprehensive guide offers insights into the nuances of multiple brick types, aiding in informed decision-making.

For those looking to venture into fly ash brick production, investing in a quality fly ash brick making machine can prove beneficial. With the right machinery, production can be streamlined, further accentuating the economic advantage.

Informative article ,thanks for sharing

Thanks a lot sir.