Table of Contents

When it comes to the age-old craftsmanship of brick creation, the pivotal choice of the right press is indispensable. “Brick Making Press Selection” isn’t just about choosing a piece of equipment; it’s about aligning technology with tradition to produce the finest bricks. As brick crafting has evolved through the ages, integrating state-of-the-art technology has become essential. One central aspect of this technological integration is the press type used, turning raw materials into fully-formed bricks. With the right brick making press selection, manufacturers can profoundly influence the quality and output of brick production. Power presses and hydraulic presses stand out in this selection process.

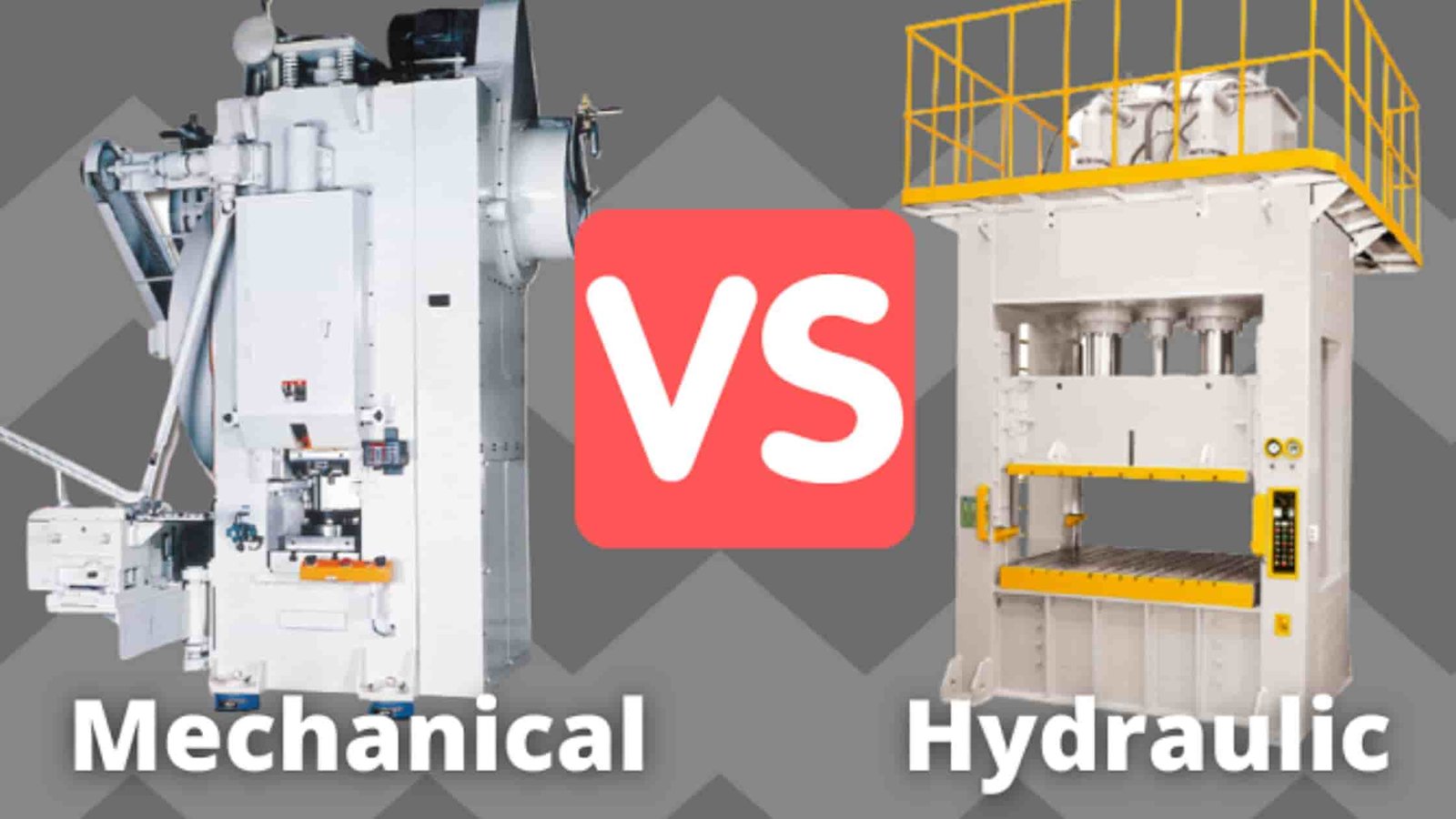

Brick crafting, an ancient artistry, has evolved dramatically with the progression of technology. Central to this evolution is the press type chosen for transforming raw elements into bricks. The pivotal choice between power presses and hydraulic presses can profoundly influence brick production. Let’s dissect the unique traits of each press to determine which is the optimum for producing fly ash and clay bricks.

An Introduction to Press Varieties

Mechanical Power Press: Commonly referred to as a mechanical press, this equipment shines in metalworking and forming fields. It relies on mechanical might to drive functions like metal bending, shearing, and hole punching. These presses are famed for their immediate, powerful force application—perfect for tasks that call for impactful loads.

Hydraulic Press: Standing in contrast, hydraulic presses leverage hydraulic cylinders to produce force. They harness hydraulic fluid, causing the press’s piston to move and apply force to materials consistently. They are revered for delivering stable force over an extended period, making them the go-to for precision-demanding tasks.

Distinguishing Load Types: Impact vs. Sustained Force

The crux of differentiation between these presses is the force nature they exhibit during operation.

Power Press Load: These presses offer impact loads with immediate force application. They excel in quick shaping or material cutting tasks. Yet, without vigilant management, the force could instigate structural problems.

Hydraulic Press Load: Renowned for providing a sustained force, hydraulic presses ensure even compaction, reducing structural vulnerabilities. This trait is a boon for precision-focused tasks.

Brick Making Press Selection: Identifying the Ideal Press for Brick Production

Making Fly Ash Bricks: Comprising fly ash, cement, sand, and water, the preferred press for fly ash bricks is the hydraulic one. Its force uniformity leads to bricks of even density and robust strength. The Brick Making Hydraulic Press is an apt solution for this purpose.

Creating Clay Bricks: In clay brick crafting, which harnesses clay among other materials, both hydraulic and mechanical presses have a role. The choice between them hinges on production magnitude and clay mix properties. With hydraulic presses offering force precision, they’re ideal for large-scale operations demanding even compaction. Meanwhile, mechanical presses, although more forceful, are apt for smaller ventures, ensuring no brick defects like cracks.

Read more about difference between Fly Ash Bricks and Clay Bricks here.

In-Depth Analysis: Mechanical vs. Hydraulic Presses for Brick Creation

When comparing these presses for brick production, consider:

| Feature | Power Press | Hydraulic Press |

|---|---|---|

| Force Mechanism | Quick and forceful | Gradual and steady |

| Load Characteristic | Impactful | Constant |

| Strengths | Speedy shaping | Precision, consistency |

| Recommended Usage | Specific roles | Uniform compaction |

| Compatibility | Certain brick types | Multiple brick types |

| Production Suitability | Small to medium scale | Medium to large scale |

| Adjustability | Somewhat limited | Highly adjustable |

Deciphering the Best Press for Brick Making

Ultimately, pinpointing the right press for brick creation depends on factors like brick type, production size, and envisioned results. While hydraulic presses are synonymous with control and consistency, mechanical presses, under meticulous monitoring, can be just as proficient. Knowledge-driven choices pave the way for streamlined brick production.

It’s vital to underscore that regardless of the press selection, extensive training, routine maintenance, and stringent safety measures are indispensable. They guarantee seamless and safe brick manufacturing.

With a profound understanding of these press features, you’re poised to make enlightened choices, propelling brick creation into a domain of unparalleled accuracy and superiority. Consequently, every brick emerges as a beacon of masterful quality and design.