Introduction

Fly ash bricks have emerged as a sustainable alternative to traditional clay bricks, contributing to eco-friendly construction practices. These bricks are primarily composed of fly ash, a byproduct of coal combustion, and are known for their environmental benefits. This article will delve into the two main types of fly ash bricks: FAL-G bricks and Cement bricks, exploring their compositions, advantages, disadvantages, uses, and the specific mix ratios used in their production.

Table of Contents

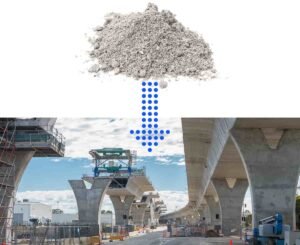

What are Fly Ash Bricks?

Fly ash bricks are a type of construction material designed to utilize fly ash, a waste product generated by burning coal. The manufacturing process involves combining fly ash with other materials to create bricks that are both sturdy and environmentally friendly. These bricks have gained popularity as they offer a sustainable solution for the construction industry, reducing the reliance on conventional clay bricks.

Types of Fly Ash Bricks:

FAL-G Bricks:

FAL-G bricks consist mainly of fly ash, serving as the primary constituent. The binder used in FAL-G is a mixture of lime and gypsum. Sand or stone dust is added as a filler to enhance the structural integrity of the bricks.

General Composition:

- Fly Ash: 50-60%

- Sand/Stone Dust (Filler): 30-40%

- Lime: 10-15%

- Gypsum: 2-5%

Advantages:

- Environmentally Friendly: FAL-G bricks contribute to eco-friendly construction by utilizing fly ash, a waste material.

- Cost-Effective: The production cost of these bricks is often lower than that of cement bricks.

- Thermal Insulation: These bricks offer better thermal insulation properties compared to conventional bricks.

Disadvantages:

- Slower Setting Time: The setting time for FAL-G bricks is relatively slower compared to cement bricks.

- Limited Strength: These bricks may have slightly lower compressive strength compared to cement bricks.

Uses:

- Residential Construction: FAL-G bricks are suitable for various residential construction applications.

- Partition Walls: These bricks are commonly used in the construction of partition walls.

Cement Bricks:

Cement bricks, like FAL-G bricks, have fly ash as the main constituent. However, in this type, the binder used is cement. Sand or stone dust is added as a filler to improve the overall characteristics of the bricks.

General Composition:

- Fly Ash: 40-50%

- Sand/Stone Dust (Filler): 30-40%

- Cement: 10-15%

- Lime: 2-5%

Advantages:

- High Compressive Strength: Cement bricks exhibit high compressive strength, making them suitable for load-bearing structures.

- Faster Setting Time: Cement bricks generally have a faster setting time compared to FAL-G bricks.

- Versatility: These bricks can be used in various construction applications due to their strength and durability.

Disadvantages:

- Environmental Impact: Cement production has a higher environmental impact compared to the lime-gypsum mixture used in FAL-G bricks.

- Higher Production Cost: Cement bricks may have a higher production cost compared to FAL-G bricks.

Uses:

- Structural Elements: Cement bricks are often used in the construction of structural elements like columns and beams.

- Commercial Buildings: These bricks find applications in the construction of commercial buildings and industrial structures.

FAL-G Bricks vs Cement Bricks

| Criteria | FAL-G Bricks | Cement Bricks |

|---|---|---|

| Primary Constituent | Fly Ash | Fly Ash |

| Binder | Lime + Gypsum | Cement |

| Filler | Sand/Stone Dust | Sand/Stone Dust |

| Composition Mix Ratio | Fly Ash (50-60%), Sand/Stone Dust (30-40%), Lime (10-15%), Gypsum (2-5%) | Fly Ash (40-50%), Sand/Stone Dust (30-40%), Cement (10-15%), Lime (2-5%) |

| Advantages | – Environmentally Friendly | – High Compressive Strength |

| – Cost-Effective | – Faster Setting Time | |

| – Thermal Insulation | – Versatility | |

| Disadvantages | – Slower Setting Time | – Environmental Impact |

| – Limited Strength | – Higher Production Cost | |

| Common Uses | – Residential Construction | – Structural Elements |

| – Partition Walls | – Commercial Buildings |

Conclusion:

In conclusion, both FAL-G bricks and cement bricks offer unique advantages and disadvantages. FAL-G bricks stand out for their environmental friendliness and cost-effectiveness, making them suitable for residential construction and partition walls. On the other hand, cement bricks excel in structural applications, offering high compressive strength and versatility. The choice between FAL-G and cement bricks depends on the specific requirements of the construction project and the emphasis placed on environmental considerations. As the construction industry continues to evolve, the use of fly ash bricks, in its various forms, will likely play a crucial role in sustainable building practices.