Embarking on the journey of constructing a building prompts a crucial question: What holds more significance in construction, cement or bricks? Amidst the myriad of construction elements, scrutinizing bricks becomes imperative for building your dream home. Let’s delve into the intricacies of two types of bricks – Fly Ash Bricks and Regular Clay Bricks – exploring five key distinctions.

Table of Contents

Unveiling Regular Clay Bricks

Regular clay bricks, a timeless building material, trace their roots back to ancient civilizations. Crafted from a blend of clay and water, these bricks evolved with hardening techniques, progressing from solar drying to industrialized ovens. Their strength and durability expanded over time, offering resistance to rust, corrosion, decay, and distortion.

In stark contrast to many man-made products, clay bricks exhibit remarkable longevity, requiring minimal maintenance. Resistant to moisture-induced size variations, these bricks uphold their appearance and structural integrity. The evolution of hardening techniques ensures that clay bricks endure without deterioration.

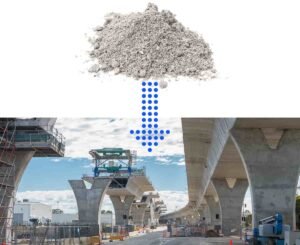

Introducing Fly Ash Bricks

A contemporary innovation, fly ash bricks represent a notable advancement. Comprising fly ash, cement, sand, and water, these bricks boast a pleasing appearance, uniform size, and a smooth polish. Their production reduces the need for mortar in brickwork and plastering, enhancing efficiency by 40–50%.

Distinguished by impermeability and durability, fly ash bricks mitigate wall wetness during the monsoon season. Notably, they are environmentally friendly, crafted from byproducts of coal burning in thermal power plants. This eco-conscious approach minimizes waste and environmental impact.

Fly Ash Bricks and Regular Clay Bricks: 5 Key Differences

- Ingredients Used:

- Fly ash bricks incorporate cement, lime, sand, fly ash, and gypsum, utilizing byproducts from coal-burning industries.

- Regular clay bricks employ natural soil, including clay, sand, lime, iron oxide, and magnesia.

- Strength and Quality:

- Fly ash bricks exhibit consistent strength and quality, surpassing the variable strength of regular clay bricks.

- Finishing:

- Regular clay bricks often require polishing for a smooth surface, given their discordant appearance.

- Fly ash bricks boast a uniform, smooth texture on both sides, reducing the need for extensive plastering.

- Environmental Impact:

- Fly ash bricks contribute to environmental preservation by utilizing a byproduct that would otherwise be discarded.

- Regular clay bricks involve the removal and manipulation of topsoil, potentially impacting natural resources.

- Resistance from Termites:

- Regular clay bricks, composed of clay, are susceptible to termite infestation.

- Fly ash bricks, crafted from inorganic ingredients, demonstrate termite resistance.

Informed decision-making during construction necessitates understanding the nuances of materials. Now equipped with knowledge about the distinctions between fly ash bricks and regular clay bricks, you can make informed choices for your building’s construction, ensuring it stands the test of time.

Table of Differences Between Fly Ash Bricks and Regular Clay Bricks

To facilitate a clearer understanding of the disparities between Fly Ash Bricks and Regular Clay Bricks, the following table succinctly outlines five key differences:

| Criteria | Fly Ash Bricks | Regular Clay Bricks |

|---|---|---|

| Ingredients Used | Cement, lime, sand, fly ash, and gypsum. | Clay, sand, lime, iron oxide, and magnesia. |

| Strength and Quality | Consistent strength and quality. | Variable strength; inconsistent quality. |

| Finishing | Uniform, smooth texture on both sides; reduced need for plastering. | Discordant appearance; may require polishing for smoothness. |

| Environmental Impact | Crafted from byproducts, minimizing waste and environmental harm. | Involves removal and manipulation of topsoil; potential impact on natural resources. |

| Resistance from Termites | Termite-resistant due to inorganic composition. | Susceptible to termite infestation, as they are made of clay. |

Arming yourself with knowledge about these distinctions empowers you to make informed decisions during the construction process, ensuring the longevity and efficiency of your building.

Hydraulic brick making machines:

Hydraulic brick making machines play a pivotal role in the context of the above-discussed article on Fly Ash Bricks versus Regular Clay Bricks. These advanced machines leverage hydraulic pressure to mold and compress raw materials, ensuring the production of high-quality bricks.

In the case of fly ash bricks, the hydraulic process aids in creating a uniform and smooth texture, contributing to their consistent appearance on both sides. This technology also proves essential for regular clay bricks, as it enables precise shaping and compression, addressing the inherent variability in clay-based materials.

The efficiency and precision afforded by hydraulic brick making machines align with the modern construction industry’s demand for quality and uniformity, whether working with traditional clay or innovative fly ash bricks.