Table of Contents

Introduction to Fly Ash Bricks Making Process:

In the world of sustainable construction, the bricks making process has carved a significant niche, especially when fly ash is the primary ingredient. This byproduct of coal combustion presents an environmentally responsible twist to traditional construction materials. By harnessing fly ash, we diminish waste and promote the conservation of natural resources. This guide delves deep into the bricks making process, enriched with wisdom from Development Alternatives.

Essential Components:

Initiating the bricks making process demands a clear understanding of the core materials. The essentials encompass:

- Fly Ash: Sourced directly from thermal power stations, this component is often free or modestly priced.

- Sand/Stone Dust: This filler augments the final quality of the brick, ensuring sturdiness.

- Lime: Beyond being a binder, lime solidifies the matrix of the brick, ensuring durability.

- Gypsum: An essential additive, gypsum refines the setting time, ensuring uniformity throughout.

Step 1: Mixture Creation – The Perfect Blend:

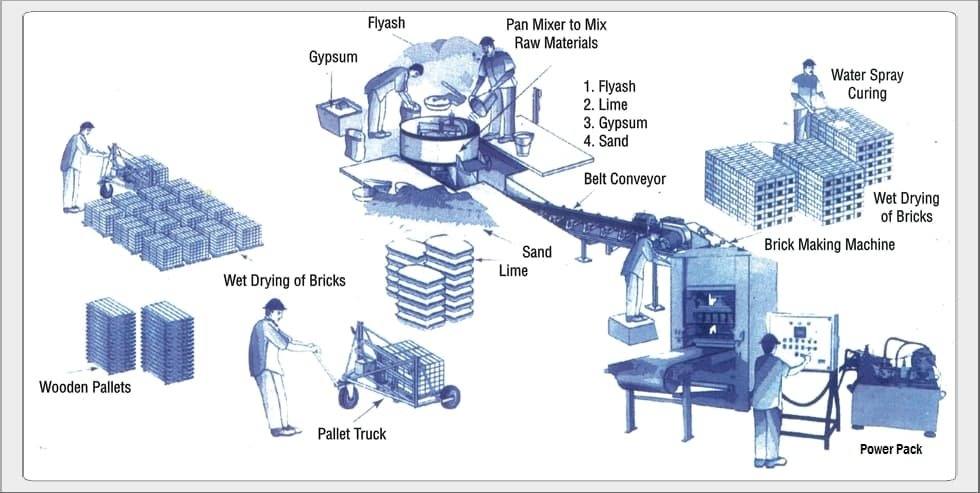

The crux of the bricks making process hinges on concocting the ideal mixture. A harmonized ratio of components ensures the brick’s strength and longevity. A blend ratio of fly ash, sand/stone dust, lime, and gypsum at 60:30:10:1.5 (by weight) is recommended. Efficient mixing tools, like a pan mixer, are pivotal for a homogenous mixture.

Step 2: Moulding – Crafting the Bricks:

With the mixture set, it’s time for the transformative phase in the bricks making process: moulding. Here, hydraulic machines or manual methods can be employed. The choice of moulds—typically made from mild steel or cast iron—varies based on design preferences. Clean, lubricated moulds ensure a seamless brick formation.

Step 3: Curing – Solidifying the Foundation:

Every brick, post-moulding, undergoes a critical curing phase for at least 14 days. This phase crystallizes the brick’s strength. Natural curing entails placing bricks in shaded regions, safeguarded with sand or gunny bags. In contrast, artificial curing utilizes chambers with controlled environments.

Step 4: The Assurance of Quality:

No bricks making process is complete without rigorous quality checks. Standards are maintained by monitoring factors like the mixture consistency, moulding methods, and curing periods. Periodic evaluations include:

- Compressive Strength: This metric quantifies a brick’s resilience.

- Water Absorption: Highlights the moisture retention capacity of a brick.

- Efflorescence: A test to check soluble salts on the brick surface.

- Dimensional Stability: Assesses any size fluctuations due to moisture.

Environmental and Economic Impacts

The decision to integrate fly ash in the bricks making process stems from both environmental and economic motivations. Environmentally, it offers a method to repurpose waste from power plants. Economically, sourcing fly ash often incurs little to no cost. Thus, the bricks making process with fly ash becomes a model of sustainable and affordable construction.

Concluding Remarks:

The bricks making process, illuminated by insights from Development Alternatives, presents an avenue for both established and budding constructors. It underscores the importance of eco-conscious decisions in construction. By adhering to this guide, one crafts bricks that stand the test of time, are eco-friendly, and are cost-efficient. The future of construction is green, and fly ash bricks are leading the way.

“In the realm of sustainable construction, fly ash bricks are witnessing a surge in demand, especially in regions like India. A recent article titled “Demand for Fly Ash Bricks in India: Bright Future of Green Building – Why it should be your no.1 delves into the reasons for this rising trend, emphasizing their green-building potential and why they’re becoming a primary choice for eco-conscious builders.

If you’re keen to embark on this sustainable journey, investing in tools like the Fly Ash Brick Making Machine can significantly streamline the bricks making process, ensuring you’re well-equipped to cater to the increasing demand.